PU synthetic leather

What’s PU Synthetic Leather

Definition

- The synthetic leather is made with PolyUrethane resin. It can be coated on substrates or dipped into substrates.

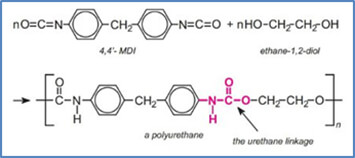

- PolyUrethane is any polymer consisting of a chain of organic units joined by urethane (carbamate) links.

(-NH-CO-O-) in molecular structure.

Characteristics

- PU resin has lots of functions that can apply for shoe making material and other industries. Features of PU are advantage in hydrolysis, bonding strength, abrasion and flexibility…..etc

Producing process of PU synthetic leather

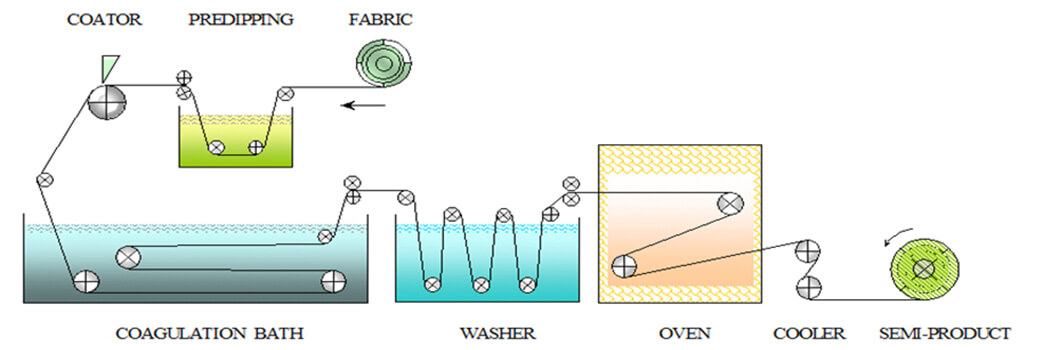

Wet Process

Enhance hand-feel and get strong physical properties

Flow Chart of Wet process

Fabric

Predipping

Coator

Coagulation Bath

Coagulation Bath

Oven

Semi-Product

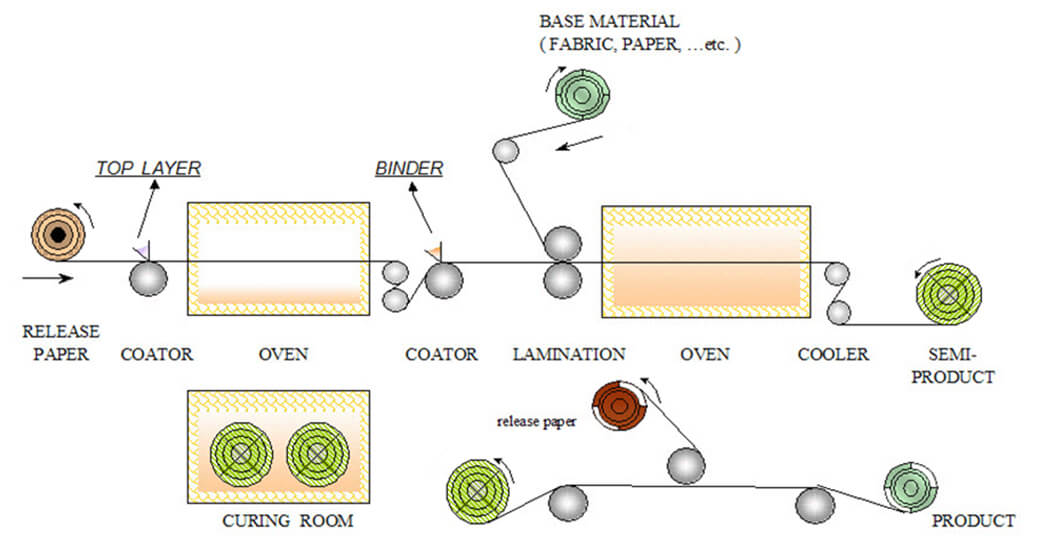

Dry Process

To get colors, effects and texture.

Flow Chart of Dry process

Bar tape processing

- Perforation

- Embossing (need to open tooling)

- Stitching

- Screen Printing (need to open tooling)

The different Treatment after bar tape process

- T2 – friction enhance

- T6 – tacky feel - recommend for golf grip

- TT30 – easy to clean - usually used on baseball grip & bicycle bar tape